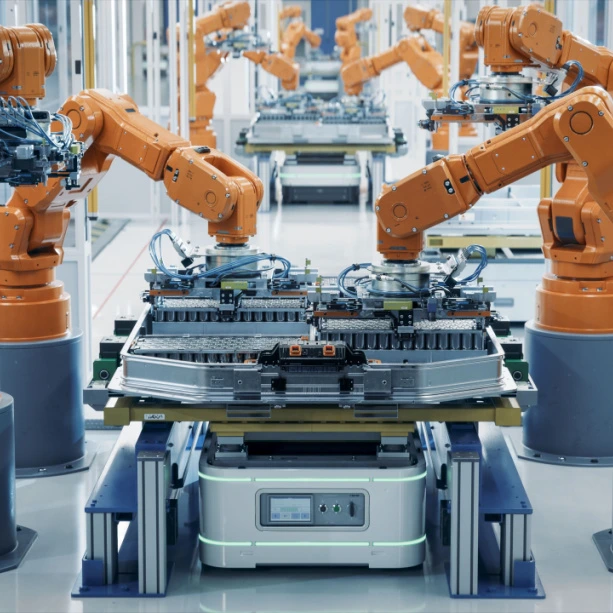

Asset Tracking for Manufacturing

Increase process efficiencies in your manufacturing plant by asset tracking with AirFinder.

Increase process efficiencies in your manufacturing plant by asset tracking with AirFinder.

Manufacturing companies face many pressures as they are expected to get things done on a day-to-day basis. An ability to increase efficiency rates within the workplace would be a huge boost to companies in the sector. With asset tracking, companies can avoid slow production times and increased labor costs as they can track and monitor important assets in near real-time.

The promise of IoT rests on a foundation of real-time location and condition information. Actions can be taken to improve business performance with this information. Yet often, due to the inherent nature of connectivity challenges, real-time visibility is only available a large percentage of the time. AirFinder provides better than "good enough" accuracy.

Here are some ways that an asset tracking system can improve productivity for manufacturers.

With detailed work-in-progress analysis, manufacturers can actively track their goods as they proceed through the production process. This can show where your “weak” areas may be so that you can find a way to fix them.

With large manufacturing companies, the ability to have visibility on assets that are being transported would be of extreme benefit. Lost items in transportation can cause delayed production, lost time, and unnecessary expenses. Asset tracking can eliminate the chances of items that go missing while on the move and can also help with scheduling so that items will be delivered on time.

Ensure that temperature-sensitive items are handled properly when they are being created, stored, or shipped. By having an IoT-based asset tracker, critical alerts can be set up when products are not in their required temperature range.

Assess which resources are being used and how they are being used to create the most value during your operations. Improving allocation also helps make sure that employees have everything they need to complete their tasks.

By tagging assets, you can decrease productivity downtime that is spent looking for them. This can also come in handy for auditing purposes as inventory is kept track of more accurately.

Having an RTLS can provide reports and analytics that can help your company efficiently manage your processes.

Find the bottlenecks in the workplace and improve the process to eliminate delays in your operations.

manufacturing

Trends help companies determine what they should be doing about common challenges and the modern business landscape. Operators

Read More