Cold Chain Monitoring

Monitoring temperatures during storage and transportation to ensure product safety.

Monitoring temperatures during storage and transportation to ensure product safety.

![use cold chain monitoring systems to monitor the temperature of sensitive food]](https://www.link-labs.com/hs-fs/hubfs/Thumbnails-08%20(1).webp?width=3001&height=3001&name=Thumbnails-08%20(1).webp)

Temperature monitoring is critical in various industries. If the temperature is not properly monitored, assets may reach a dangerous temperature and no longer be safe for use or consumption.

Cold chain temperature monitoring devices, like AirFinder, monitor the real-time temperature of foods and other sensitive assets and send alerts to the end user when the food is close to an unsafe temperature. Remote cold chain monitoring serves as a safeguard to maintaining quality.

IoT cold chain monitoring has a few capabilities that make it useful for those who move food through their supply chain.

Know the status of your products in real-time

Ensure met compliance regulations by making sure sensitive assets are maintained at specific temperatures for safe consumption or use

Deliver food at the highest standard and address any issues with the temperature range before it’s too late

When the temperature starts to move away from the proper temperature, receive an alert to address the situation immediately

.webp?width=450&height=450&name=Thumbnails-09%20(1).webp)

There are various industries that can profit and benefit from monitoring their cold chain.

Track and monitor sensitive foods items during transport and storage so they can be consumed safely

Monitor pharmaceuticals in real time to meet compliance regulations and ensure the health of patients

Detect changes in the environment where critical chemicals are being stored or transported in

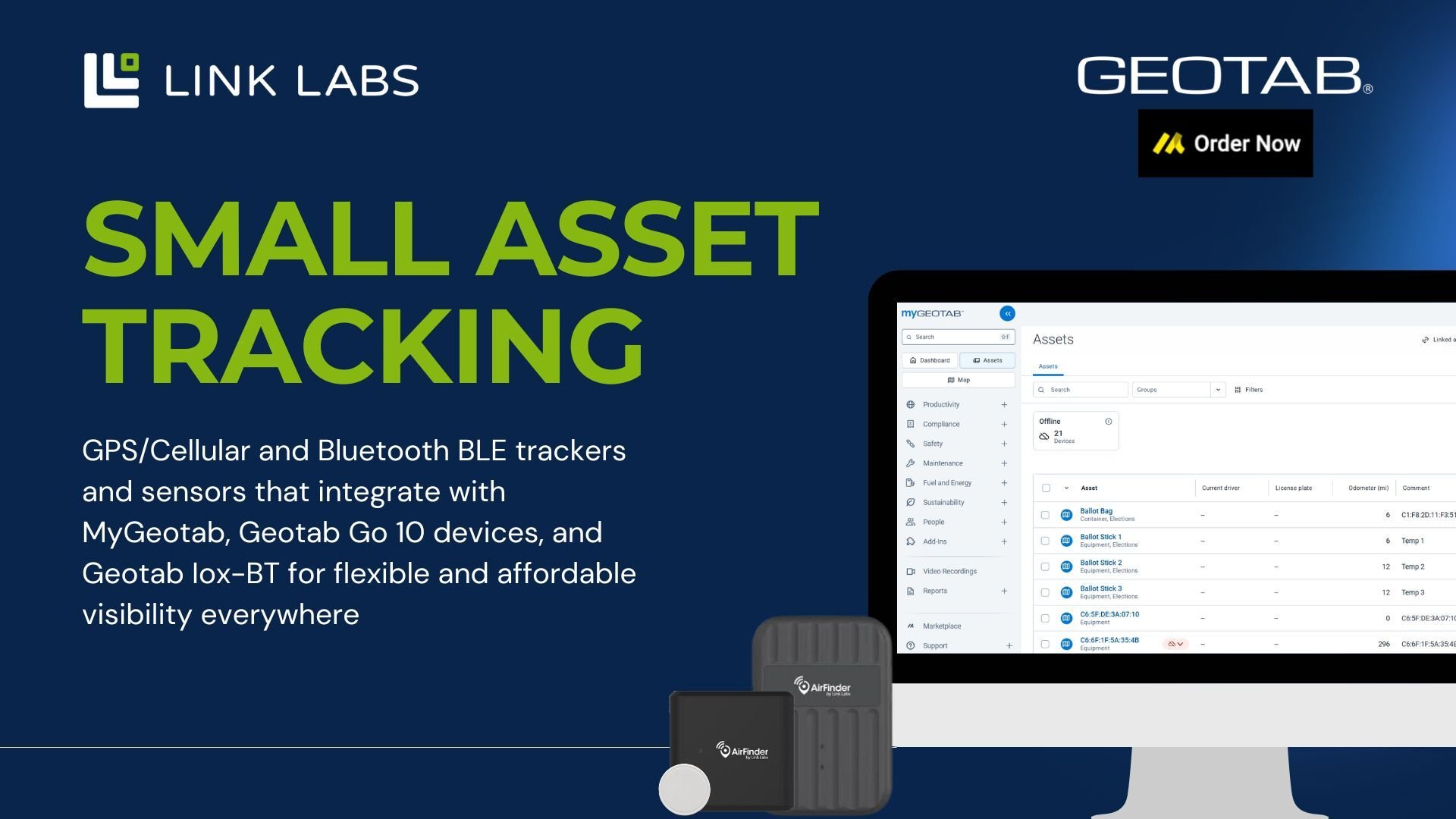

Today at Geotab Connect 26, Link Labs is proud to announce the launch of our Small Asset Tracking solution fully integrated into

Read More