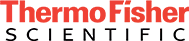

Asset Tracking for Manufacturing Operations

Track your inventory and equipment to maintain complete visibility of your manufacturing process and improve production uptime.

Track your inventory and equipment to maintain complete visibility of your manufacturing process and improve production uptime.

For manufacturing operations, nothing is more important than promoting a streamlined production process that maximizes uptime and efficiency. Asset tracking can be used to provide process visibility and enable real-time operational decisions. By implementing an asset visibility solution, operators can improve productivity and reduce search times. Employees can use their time to focus on what they were really hired to do instead of spending time recovering tools and materials.

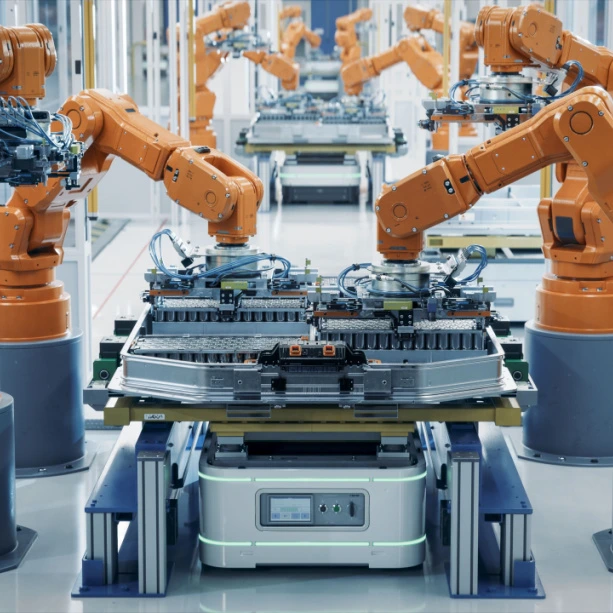

WIP tracking provides full visibility of inventory as it moves through the production process. This empowers operators to improve process efficiency by providing detailed data on productivity and inventory progression.

Learn more about WIP tracking

Tool tracking enables the reduction of search time and improvement of overall productivity with real-time visibility. This also helps improve equipment life expectancy by providing vital usage data and maintenance records.

Learn more about tool tracking

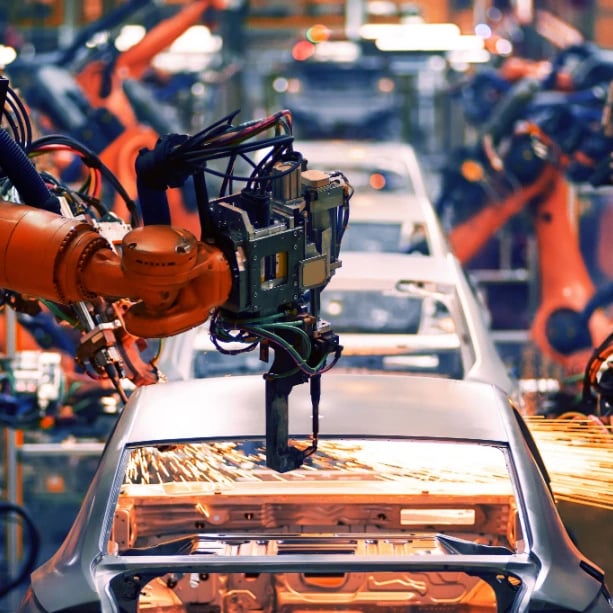

Heavy equipment tracking enables the reduction of search time and improvement of overall productivity. This also helps improve equipment life expectancy by providing vital usage data and maintenance records.

Learn more about heavy equipment

.webp?width=613&height=613&name=istockphoto-1043169994-170667a%20(1).webp)

Ensure that waste is minimized and disposed of properly with asset tracking. Retain awareness of and address unexpected upticks in waste. Further, ensure that scrap materials being stored are not mistakenly disposed of.

Learn more about waste reduction

Manage raw material and inventory that requires processing. Understand how your materials are used, know how much you have in stock, and catch production errors early so you never waste money on unnecessary orders again.

Learn more about raw material

Maintain visibility of finished goods that have exited your production process. Improve awareness of your output and inventory to better serve your customers, track operational productivity, and make progress toward business goals.

Learn more about finished goods

Provide accurate, accessible documentation to prove adherence to industry regulations and avoid potentially hefty fines.

Read more about compliance

Maintain visibility of the entire production process to identify potential improvements and address challenges before they arise.

Read more about process efficiencies

Reduce search times and improve production uptime by tracking materials, tools, and inventory across your facility.

Read more about loss prevention

Rental equipment is extremely valuable, leading to theft being a prominent issue. You can avoid these large replacement costs by implementing a system that tracks your equipment’s location in real-time. If equipment is stolen, you can retrieve it instead of replacing it.

Learn more about asset tracking for equipment rental companies

Finished products are at times stored in on-site warehouses until it is time to have them shipped out. These products may remain in the warehouse for any length of time. Keeping track of what products are stored and where they are can pose an obvious challenge.

Learn more about asset tracking for warehousing

An asset tracking solution allows your company to track remote to increase visibility and provide real-time data on shipments and equipment. Your company will now have visibility throughout every step of the process to ensure that your goals are met.

Learn more about asset tracking for logistics operations

Any number of obstacles can stand in the way of maximizing operational efficiency. Misplaced tools or inventory, inaccurate data reporting, and unexpected downtime can all contribute. Asset visibility provides a solution for all of these problems and more. The real-time data provided through these systems can also help operators understand the strengths and weaknesses of their business processes. This provides data-driven opportunities for increased efficiency and overall improvement.

manufacturing

Trends help companies determine what they should be doing about common challenges and the modern business landscape. Operators

Read More