Warehouse Asset Tracking

Whether you are responsible for managing the inventory in your retail backroom or a manufacturing distribution center, having visibility of all your assets is necessary for a productive and compliant warehouse.

Whether you are responsible for managing the inventory in your retail backroom or a manufacturing distribution center, having visibility of all your assets is necessary for a productive and compliant warehouse.

Although many warehouses use some form of RFID for asset tracking, visibility is limited to the last interaction between the tag and RFID reader. In order to have continuous location accuracy, warehouses need to implement a Real-Time Location System.

With AirFinder Onsite, your company can increase visibility with one system that is simple to install and adjust. This unique solution is capable of solving all your warehouse needs.

The obvious answer is that it saves money. But here are a handful of broad reasons that can improve your companies return on investment.

One way warehouses use tags for RTLS is on team members, visitors, and contractors. These wearable tags can come as a necklace, a wristband, a watch, a pen, a belt, and even a hardhat. The question is, “What kind of wearable tag will work best for your people?”

RTLS tags are excellent for tracking inventory as it makes its way through a production process. Whether it is storage, distribution, or manufacturing, RTLS tags can assist managers. Knowing location and tracking progress can limit booking errors, streamline workflow, and shorten lead-time.

When essential equipment is lost, the warehouse is at risk of losing thousands of dollars or missing production or shipping deadlines. RTLS tags optimize the role of all assets, maximizing utilization while minimizing misuse.

During emergencies or emergency drills, managers want the visibility of knowing who has and has not evacuated the building.

Everyone in the warehouse can visualize the location and progress of assets in real-time.

RTLS analytics can provide the information you need for documentation.

Real-time data helps utilize the process of the fleet with heat maps, route optimization, and shock sensing.

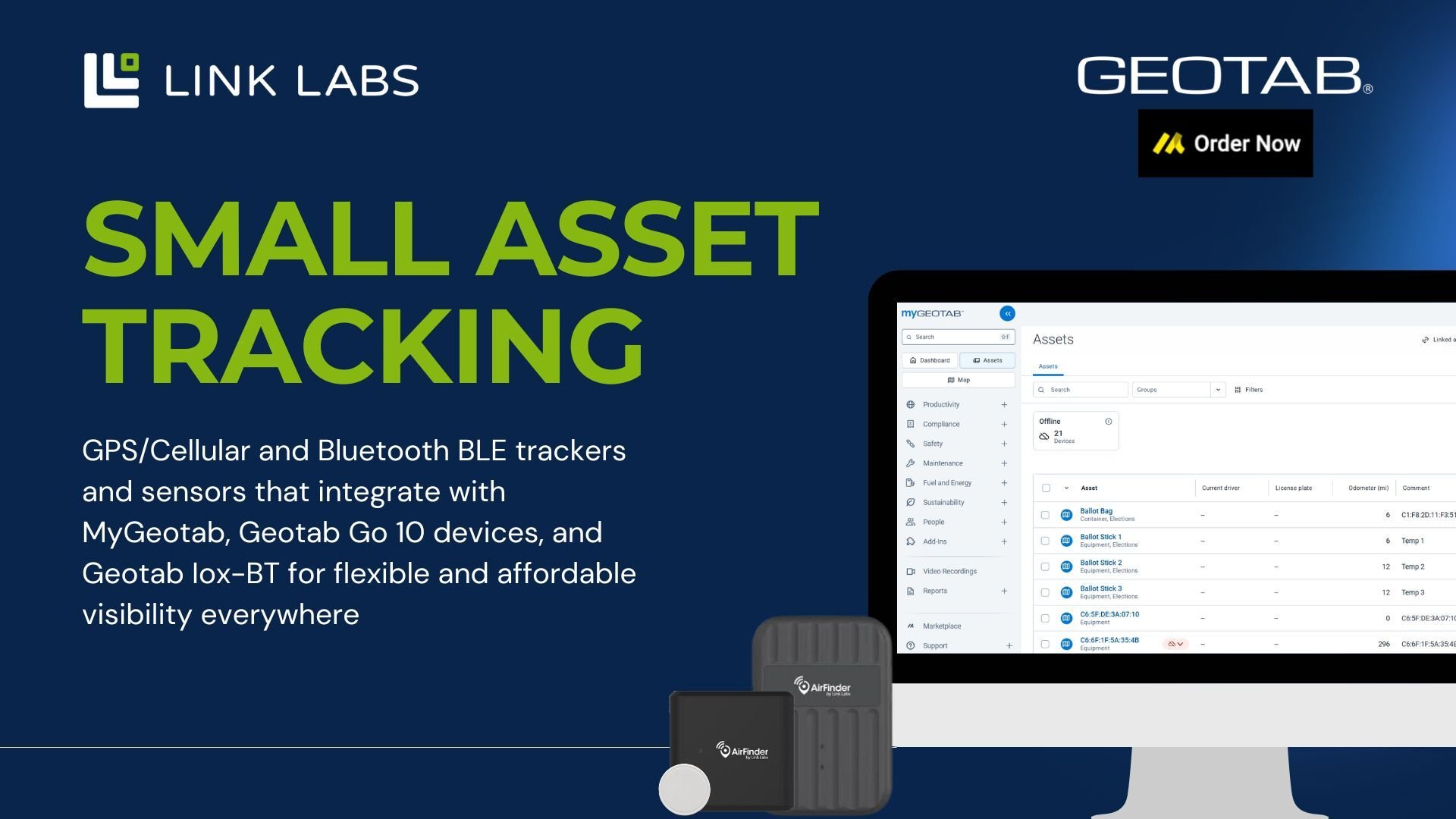

Today at Geotab Connect 26, Link Labs is proud to announce the launch of our Small Asset Tracking solution fully integrated into

Read More