Accuracy and Precision are important metrics for choosing an asset tracking system for manufacturing and healthcare applications. Essentially, this metric is how close the reported location is to the actual location. In many sales conversations, new AirFinder customers assume that more precision is better, but this may not always be the case. It always comes down to the use case, and importantly, the cost and complexity of the system.

Take the age-old example of infusion pump tracking in a hospital setting. Biomedical staff need to be able to find these pumps to do maintenance, etc. Knowing what room these pumps are in is critical, but knowing precisely where in the room it is located would be overkill. When the engineer walks in the room, he’ll be able to find it. This is an example of “room level accuracy.”

On the other extreme is true X-Y-Z location tracking which would be needed in an automated warehouse. When a box of goods is placed on Shelf 6, Bay B, in Row C, you might say that “shelf level accuracy” is required. Just knowing what row the item is in isn’t going to help much at all.

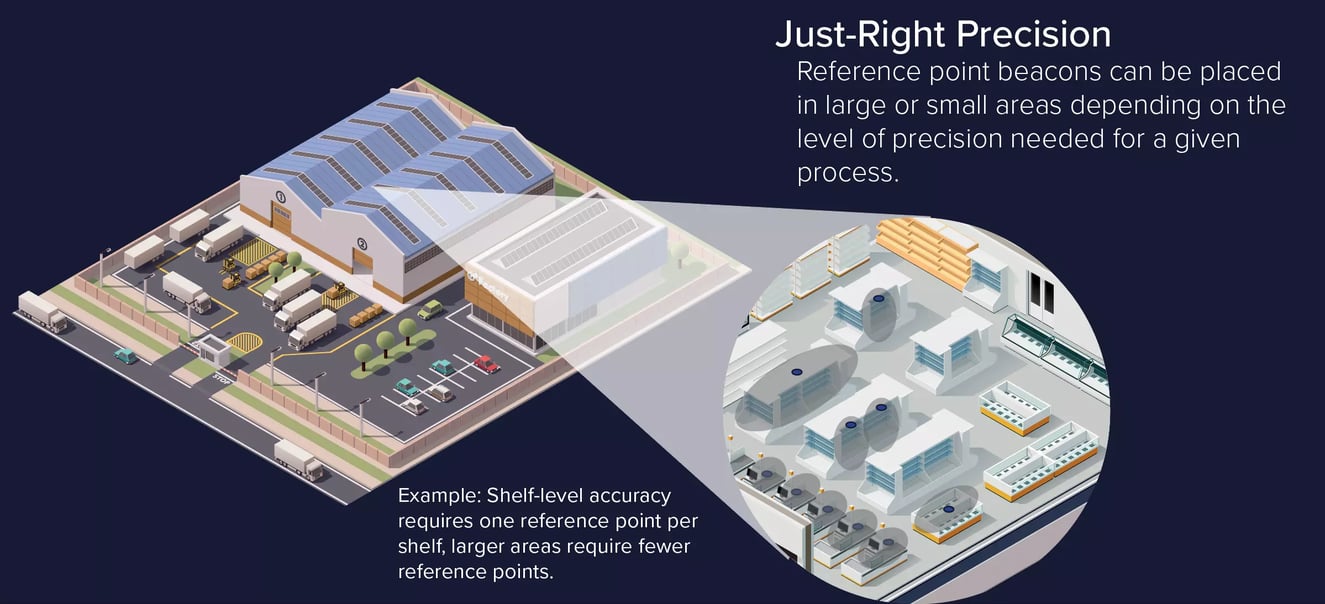

In the middle of these two extremes we have what we call “Just Right Precision.” This is the case where in some areas, room level accuracy is fine, but in other areas you need more area segmentation. In the infusion pump example, perhaps in a storage room, it would be helpful to know which quadrant a particular pump is in to speed up finding it.

Technology that enables asset tracking precision

Ultra Wideband technology is considered the most accurate for asset tracking. Indeed, this is what is used in applications that need so-called centimeter level accuracy. Zebra, for example, uses UWB to locate barcode scans in automated warehouse settings. The drawback of UWB for many use cases is that the shear volume of readers and infrastructure required makes these installations hugely expensive. When you add walls and complex structures, like hospitals, the cost makes UWB unusable. In fact, many UWB applications need to create “zones” of coverage that are reported back to the human user. It wouldn’t be very helpful to give the X-Y-Z coordinates of an infusion pump, when room 423 is the answer the biomedical engineer needs.

The Just-Right-Precision of AirFinder is enabled by adding location beacons at whatever granularity the use case requires. In the hospital setting, perhaps one beacon per room is enough. In the storage room, perhaps 4-6 beacons might be used.

The advantage AirFinder has over other BLE asset tracking systems, is that AirFinder does the location processing on the tag itself. Where other readers need to receive tag beacon messages at a central location, AirFinder tags only listen to fixed BLE location beacons, and then calculate their own position. This means that scaling up the accuracy in a given area is as easy as adding a few more location beacons, not more connected BLE readers.

Other types of technology often used for asset tracking in these same healthcare or manufacturing settings include WiFI based trackers. These systems can work great if the facility already has the appropriate type of WiFi infrastructure installed. WiFi tags also tend to be larger and more expensive than BLE based ones. In settings where WiFi is a mix of vendors or is an older system, AirFinder is a good choice.

Don’t assume that you need 1cm accuracy in your RTLS or RFID based asset tracking install. In many use cases, zone-level (room-level) accuracy, with the ability to increase precision in certain areas is a more cost effective solution.