Radio frequency identification (RFID) technology comes in two flavors: active and passive. Of the two, active RFID is the newest innovation. Over the last several years it’s made big inroads in the asset tracking market, enabling greater visibility over all types of assets at an affordable cost. For purposes of this article, however, I’m referring to passive RFID, an older system that is less advanced but still commonly deployed. As is usually the case when new innovations come on the market, some are wondering whether passive RFID asset tracking is still viable. My answer: For the right use case, absolutely. But there are a few things you should know before making that determination.

First, a quick refresher:

What’s the difference between passive and active RFID asset tracking systems?

Passive RFID systems use readers that send out a low-frequency, high-power signal to battery-free tags. The energy “wakes up” the circuit in the tag. The tag transmits a coded message back to the reader at a higher frequency and lower power.

Active RFID uses battery-powered tags that advertise their identity to various access points or readers. These readers typically found in a real-time location system (RTLS) then transfer the identity of tagged items to a gateway, which sends data to the cloud (or an on-premise server).

Is an asset tracking system using passive RFID still viable?

In my view, yes, but here’s what you need to know going in:

- Passive RFID tags are inexpensive—the majority of them cost only cents on the dollar. Low tag cost is one of the primary benefits of passive RFID, and the reason it’s used as often as it is. Companies with thousands of assets to track can attach generic tags to all of them without breaking the bank.

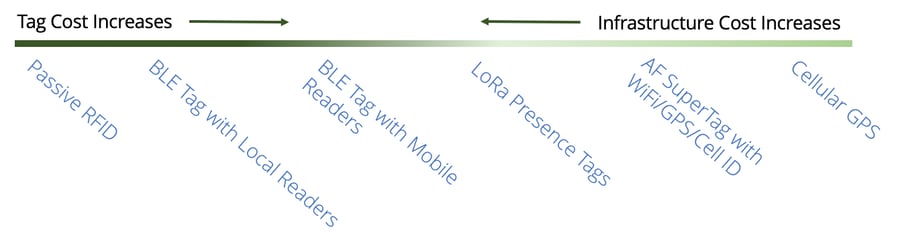

- In contrast, the infrastructure required for passive RFID asset tracking solutions is expensive. If you pare down the tag side to make them simple and cheap, the infrastructure side requires more complexity to make the system work. The same is true in reverse—if tag costs go up the infrastructure cost goes down. As you can see in the image below, passive RFID is all the way to the left, indicating the lowest extreme in terms of tag cost and the highest infrastructure cost of all the tracking systems. So where low tag cost is one of the primary benefits of passive RFID, the high cost of infrastructure is one of its primary shortcomings. Basic RFID tracking costs about a dollar a square foot for a facility, so outfitting a million-square-foot facility would cost around a million dollars. And that’s for just the basics, i.e., an asset came in or out this door, and/or an asset is in this general area. Which leads to the third important piece of information about passive RFID tracking systems…

- A very basic passive RFID tracking system delivers limited location information. Knowing if an asset passed through a location at a certain time doesn’t tell you where it is now; similarly, knowing an asset’s general location may not be sufficient to deliver the return on investment you expect (i.e., will the time you spend searching for assets be significantly reduced?). You could add more readers to improve the system’s accuracy—if you have the money to spend.

- It doesn’t lend itself to outdoor tracking. Putting readers in vehicles is a complex—and also costly—undertaking. It would require putting a $5,000 reader in a vehicle so it can scan whatever’s coming into it; the reader also has to have a backhaul, like a cellular connection.

Find out how you can track materials in your manufacturing environment for ten times less than alternative location technologies.

For a long time, passive RFID for asset tracking was the only game in town. There were—and still are—many good use cases for it, like luggage tracking, for example. Many airports outside the U.S. put passive tags on travelers’ luggage. Readers are placed on conveyor belts to scan the tags and ensure each bag is headed to the right place. Later, tags are removed and discarded. This scenario is a passive RFID home run because:

- Tens of thousands of tags are needed.

- The infrastructure cost is expensive but manageable, with readers on conveyor belts only.

- The tags are discarded after being read.

Another scenario that’s a good match for passive RFID tracking is preventing theft. Again, numerous tags are needed, they’re destroyed when assets leave the store via a checkout line, there are no batteries to worry about changing, and the number of reader stations is minimal.

When To Use An Active RFID Asset Tracking System

Ten years ago when RFID came out, a lot of active technologies weren’t very mature. As a result, some companies chose passive RFID to solve their asset management challenges and stuck with it.

Today, it’s advisable to give other technologies, like active RFID, serious consideration. Tracking millions of luggage tags around a conveyor belt is one thing, but tracking fixtures, people, and materials in manufacturing with passive technology—that’s a stretch. It simply doesn’t make sense to spend a million dollars on passive infrastructure when you could get better performance with active RFID, and spend less. Weigh the amount of money you’ll spend on a solution vs. how much you’ll save as a result of using it and, in many cases, active works out to be the better solution. (Here’s some advice on building a business case for an asset tracking solution internally.) The bottom line is that active and passive RFID serve two very different scenarios:

If you’re willing to spend a lot of money on infrastructure, you don’t need highly accurate location, and you need very inexpensive tags, passive RFID is your best option.

If you’re willing to spend less on infrastructure and more on tags, and you need highly accurate location information, intelligent RFID is a better choice.

Take A Look At AirFinder’s Intelligent Active RFID Asset Tracking Solution

If you don’t want to put up a tremendous amount of infrastructure for your use case but still need high accuracy and long battery life, check out AirFinder. The AirFinder system uses intelligent active RFID tags that wake up at certain set intervals and scan their environment to look for fixed reference point beacons in the vicinity. The tags then calculate their own locations based on the information gathered from the closest fixed beacon, and send that data to the reader as a message. (This tag-centric calculation is why this type of active RFID is considered intelligent.)

The advantage of intelligent RFID is that you can gain a great deal more location accuracy than you can with beaconing RFID. The system also minimizes battery use, requiring fewer changes than other types of systems; and it combines minimal infrastructure with relatively low tag costs, ensuring the entire asset tracking system is as cost-effective as possible. Many organizations have saved money as a result of switching to AirFinder from more costly RFID systems.

The best way to see whether it might work for you is to schedule a free demo. We look forward to answering your questions and helping you choose the right asset tracking system for your needs.