Raw Material Tracking

Manage raw material and inventory that requires processing. Understand how these materials are used, know how much you have in stock, and catch production errors early.

Replenishing raw materials is a costly element of the manufacturing process. By tracking this inventory with RTLS, you can reduce unnecessary spending on replenishing material that has been misused or misplaced. Asset visibility can also provide insight into how much material you actually use, so you only order what you need.

Tracking raw materials empowers you to reduce spending on production resources. By trusting AirFinder with your asset tracking needs, you can also gain improved understanding of your usage and processes.

Know what material is used when, as well as how long material orders last. Monitor unexpected shifts in usage to identify potential production errors.

Identify when raw materials will need to be replenished before it occurs so you can place orders ahead of time and adjust your budget accordingly.

Know exactly where your inventory is located, quickly locate anything that is moved or improperly stored, and reduce unnecessary restocking and replacements.

Retrieve raw materials without questioning their location. Quickly find the components you need, freeing more time for the actual production process.

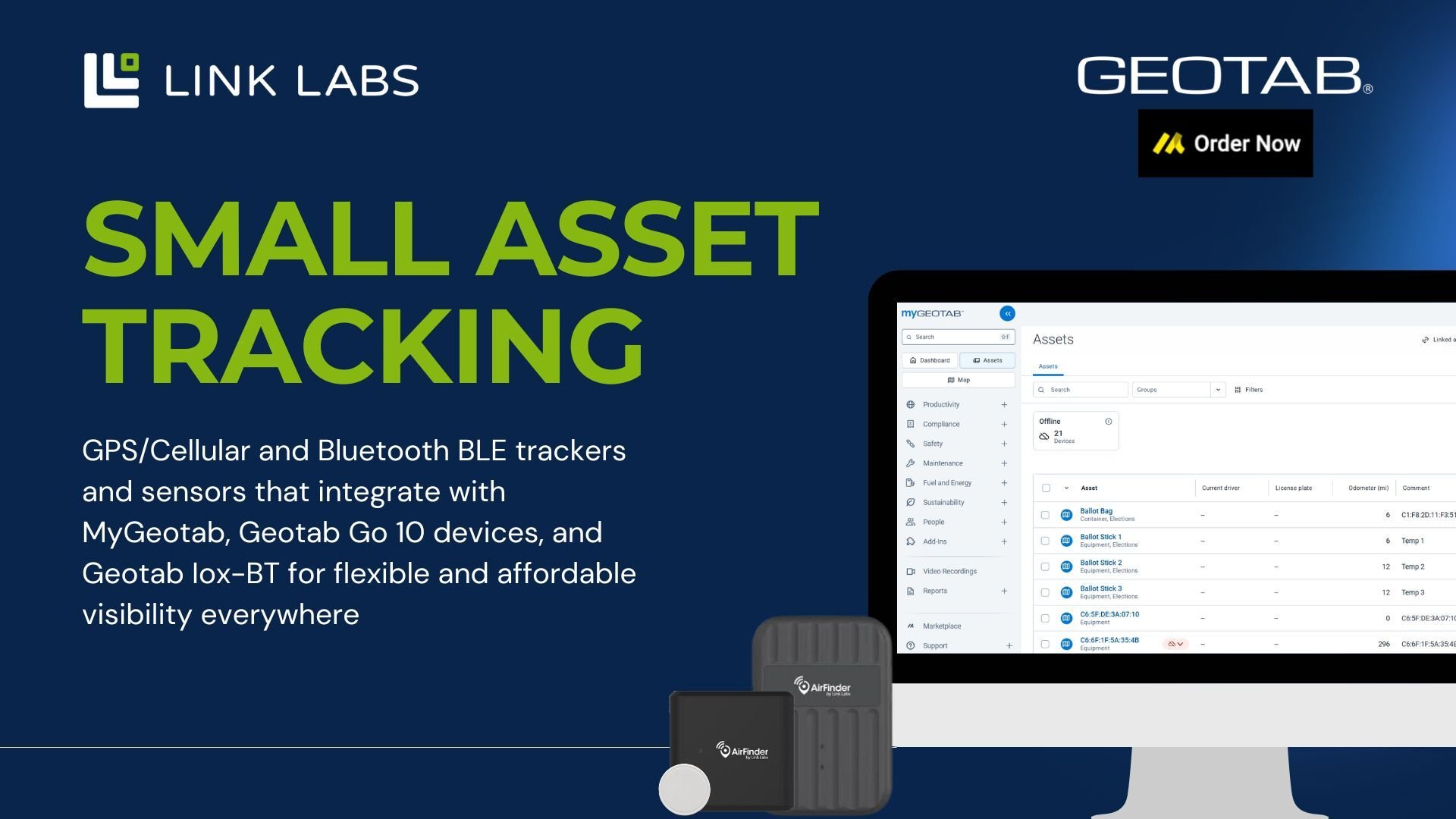

Today at Geotab Connect 26, Link Labs is proud to announce the launch of our Small Asset Tracking solution fully integrated into

Read More