Bluetooth has become the dominant wireless technology for Internet of Things devices for two reasons: it is inexpensive and readily available. Bluetooth Mesh technology attempts to address one of the drawbacks of Bluetooth, it has very short range. Bluetooth has such a great energy profile because it transmits at low power (0 dBm or less), and the data rate is very high (1 mb/s), so the time-on-air is very short. This makes Bluetooth Low Energy (BLE) a great choice for battery powered devices like wearables that link to smartphones, but the challenge of using Bluetooth in an industrial environment is that an infrastructure needs to be installed to backhaul the data. The smartphone model won’t work.

The Bluetooth Mesh Standard is being developed to allow BLE devices to network together to carry data back to a gateway device, where it can be further routed to the internet. Even though the BLE mesh specification is still under development, it will be a powerful architecture to allow low cost, battery powered devices to connect in industrial or enterprise settings.

That said, here are some cases where even Bluetooth Mesh won’t work well:

- Bluetooth Mesh Sensors are not well distributed. When you combine the short range of Bluetooth with the needs of a mesh network, the mesh design and management is critical. Bluetooth mesh would work well for sensors that are distributed nearly uniformly throughout an area (HVAC sensors, lights), but not so well for “lumpier” deployments (power monitors, paper dispensers, industrial monitors).

- Some sensors are in isolated locations. This is really a subset of the previous case, but just to drive home the point, if you have a sensor off on it’s own, it cannot join a mesh, if the neighbor node is out of range.

- High volume of sensors. Even mesh networks have throughput limitations, and the more data that the mesh needs to move around, the more power (and less battery life), each node will have.

At Link Labs, we have found the most powerful architecture for low cost Industrial IOT sensors does use Bluetooth, but not a mesh:

- Bluetooth to LTE-M: Here the Bluetooth connection is made from a low power “reader” device which is connected to the LTE Cat-M1 network directly. These low cost and low power devices act as the gateway does in a traditional Bluetooth IOT system, but are designed to be installed in high volume in an enterprise, like a factory. Every group of Bluetooth sensors would be “ganged” to one reader devices. 5-10 Bluetooth devices per LTE-M bridge is a good balance. These bridges can be powered by AC in a simple outlet, and placed in a convenient spot near the BLE sensors.

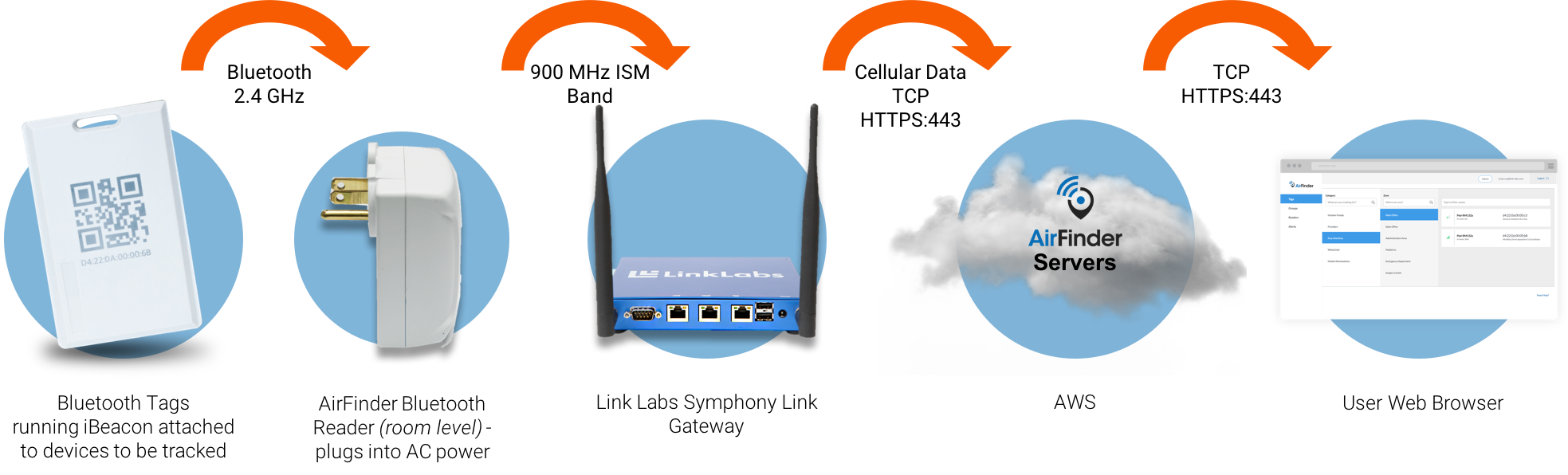

- Bluetooth to Lora/Symphony Link: For installs that find LTE-M too expensive or difficult (perhaps the cellular network is weak), the Bluetooth bridge can then transmit over long range via LoRa using Symphony Link. This is the architecture that AirFinder uses for RTLS Data. This is a very powerful combination because you combine low cost sensors with the “no IT integration” features of Symphony Link. The Lora gateway is then backhauled via Cellular or Ethernet itself.

AirFinder Architecture

Key Take Aways:

- Bluetooth is a powerful connectivity tool in an Internet of Things architect’s tool kit.

- Using smartphones for Industrial or Enterprise connectivity backhaul is not viable.

- Bluetooth Mesh is only an option for well distributed and controlled use cases, like lighting control.

- Using Bluetooth in combination with long range backhaul is the preferred way to leverage Bluetooth in Industrial IOT solutions.