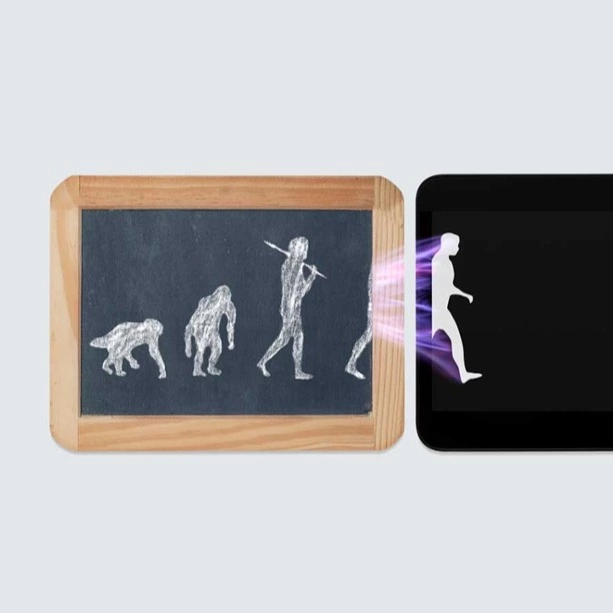

It’s undeniable that the pace of technology is moving at the speed of light. The breadth and depth of the Internet of Things (IoT) is constantly pumping life into new possibilities and pushing the envelope on digital transformation, particularly when it comes to IoT asset management.

Companies the world over are digitizing and automating business processes that were once entirely manual. Many organizations even have specialized roles dedicated to this endeavor. Lots of them come to Link Labs looking for an asset management software solution that will help them locate assets and monitor their condition while providing actionable insights.

The journey through digital transformation is always fun and often tedious. But if reaping the strategic benefits of asset management is a core component of your overall road map, you will need to factor it into your long-range trajectory.

To help you through the process, we’ve developed four stages of IoT asset management that most companies can use to benchmark where they are in their journey.

And if you’re looking for an overview of asset tracking, you’ve also come to the right place!

Stage 1: Basic Asset Tracking with Paper, Pens and Whiteboards

Practically every company on earth has some form of asset tracking in place. Maybe it’s a sign-out sheet or perhaps your employees send their colleagues emails when they are planning to use something.

I used to work at a growing tech company that had one printer. If someone was printing out a large run, and another employee made the grievous error of printing out their own job at the same time, that printer would pause the current run to print the next job.

So a sales rep might wind up at a conference with pre-printed handouts that included a rogue flight itinerary stapled within the pages. To avoid this, the office manager (or whomever was printing a large job) would send out an email asking everyone not to print and a second email confirming completion.

Same office, different problem. We had two company cars in an urban setting, which no one could ever seem to locate. I can’t count the number of emails I got saying something like, “Has anyone seen the grey Accord?”

Fortunately, times have changed and there are much better ways to track assets. But even in very sophisticated settings, you’ll probably still find rudimentary tracking systems. Think about the last time you went to a hospital; most likely there was a whiteboard somewhere on each floor detailing which patients were in which rooms. It might even have had magnetic rows so that patients could be easily moved around and updated.

While digital whiteboards are now hitting the market, they have a while yet to replace the simple wall-hung version showing where everybody is at-a-glance, because let’s face it, that can be an incredibly powerful and efficient method.

What’s more, methods of asset tracking like these are generally cheap and easy to implement - no training necessary. The downside, however, is that the data is confined to one spot (you’d have to go view the designated whiteboard) and it’s not very scalable.

For example, I did my fair share of innocently interfering on the print jobs of others!

So in moving between stages, you will want to consider how you can drive more value before getting to the next step…

Stage 2: Asset Tracking Spreadsheets

Although still somewhat popular in some corners of the business world, so-called analog methods for asset management have taken a big hit, thanks to advancements in computer technology that made digitization possible.

In fact, with the advent of Excel software in the 1980s, digital asset tracking spreadsheets quickly became the “best invention since sliced bread” for tracking and managing all sorts of assets. For one thing, they were relatively easy to use and maintain, as long as there was one person primarily responsible for data input. For another, they were relatively inexpensive, all things considered; and of course, they were also less vulnerable to natural disaster.

So, plenty of small to midsize businesses, across multiple industries, traded pen and paper for digital spreadsheets as the cornerstone of their asset management strategy. And while many are still wedded to spreadsheet solutions - especially now that Google offers a free version - a growing number are rapidly losing faith, given the many drawbacks.

Spreadsheet systems are most useful on full-sized computers and cannot easily be accessed on mobile devices. They can also be incredibly unreliable, given that they must process large volumes of manually input information, which inevitably leads to human error and inaccurate data. And let’s not forget that computers are far from infallible, in that viruses and hardware failures can potentially wipe out years of hard work if you don’t happen to use cloud storage.

On top of that, simple asset tracking spreadsheets cannot remotely track and/or locate assets in real-time; data integrity is definitely problematic; and there is no audit trail. Likewise, only one person at a time can access and edit them - thereby precluding collaboration - and it’s impossible to identify who has changed what and when unless you ask around the office. (Much like the printer and car examples.)

Equally significant, it takes a great deal of staff time and physical effort to collect, upload, update, calculate, and analyze asset data to identify meaningful trends and make good business decisions. (Although that’s assuming the information you are using is truly accurate in the first place.)

In an effort to solve some of these issues, companies created common databases for tracking assets and inventory. By organizing, structuring, and storing information in one central location, these automated digital systems do help enhance interoperability between and among different departments and functions.

They are also capable of warehousing large amounts of data, with which to determine quantities, forecast needs, and/or track the basic phases of an asset’s life cycle. But like spreadsheets, these databases require significant labor to use (i.e. analysis and reporting must still be done manually). By the same token, they are not particularly useful for developing effective business processes or making good business decisions.

Needless to say, while spreadsheets and databases have made asset management easier, they have not been game-changing in the way that IoT asset management solutions have when it comes to improving efficiency, controlling costs, and reducing risk. Which is why businesses are fast moving into Stage 3: cloud-based, asset management software solutions.

Related reading: Learn more about available asset tracking hardware options.

Before you jump on the bandwagon though, you will need to acquaint yourself with the different systems and technologies; assess your unique business needs; and choose a vendor that can help you select the best asset tracking solution to meet those needs.

Stage 3: Cloud-Based Asset Management Software

Okay, now that you’ve reached Stage 3 in your journey, you’re ready to harness the power of IoT and move into the world of real-time asset tracking and location software, using the right combination of technologies like GPS outdoor localization, WiFi, and RFID tags. At this point you are entering the realm of digitalization - or the use of digital technologies and data to adjust your business model in ways that improve your business processes.

The IoT solution you have chosen will empower you to connect people and assets, with automated systems and processes in ways you never thought possible. And in doing so, you will now have a far more effective way to increase productivity, maintain regulatory compliance, mitigate risk, and monitor your assets from anywhere, at any time, on any device.

Likewise, you have created a centralized, cloud-based system for automatically collecting, updating, and maintaining all of your data in one place, rather than distributed across multiple spreadsheets or databases. Even better, your IoT-enabled tracking system will allow multiple employees at once to access data, thereby facilitating collaboration among departments.

In fact, your company will now have the capacity to share and collectively interpret reams of asset use and condition, quantity and location data - which in turn, will improve the workflow; reduce the potential for waste; prevent equipment failure; and lower costs.

IoT-based solutions can help companies remain constantly abreast of inventory stock, so it may be proactively replenished, while also effectively managing risk and ensuring compliance, by constantly monitoring perishable goods or equipment maintenance. And an IoT-enabled system will be far more scalable, as your business grows and your needs change.

But despite the many benefits you are likely to realize during Stage 3, predictive insights and automated decision-making will not be among them. Although cloud-based tracking apps enable continuous access to accurate and complete asset data and audit reports, you will still need people to collect and correctly interpret it all before using the information to make business decisions.

For example, while asset management software solutions allow you to monitor equipment use and condition data, it must be analyzed by finance department staff, tasked with developing maintenance and depreciation schedules. The same goes for administering the asset management system, which requires staff time and energy to ensure that basic work functions are in place and operating well.

So while you are definitely moving in the right direction, there may come a time when you are ready for full-blown digital transformation, with the help of an even more sophisticated IoT asset management solution that replaces human interaction with artificial intelligence (AI).

Because this next-generation technology is still evolving, you should probably give it a bit more time before you take the leap - which you can certainly use to get a much-needed running start on making the transition into what we will call Stage 4. That said, you will want to do some groundwork, as follows:

- Create a strategic implementation plan that includes a solid budget projection for handling the upfront cost.

- Do a deep dive into your current system to fully understand the data you are collecting, so that you may decide whether they are sufficient for meeting the business problems and streamlining the business processes at hand.

- Select the data you will need going forward and clean it to improve its quality and ensure its integrity.

- Prepare your stakeholders well in advance to mitigate the resistance that inevitably goes hand-in-hand with digital transformation initiatives such as this.

Stage 4: Machine Learning and Artificial Intelligence

Perhaps the easiest way to understand Stage 4, is to look at how the next generation of IoT asset management incorporates machine learning and AI to facilitate big picture thinking - the whole forest (or enterprise) instead of just the trees (its individual assets).

Consequently, it will shift the focus from optimizing assets to maximizing impact on the entire enterprise. And in doing so, will use predictive analytics to automate business decision-making around cost savings, resource utilization, risk mitigation, dynamic sourcing, and asset maintenance and availability.

With that in mind, companies will begin to think of assets as both those they “own,” and those they obtain from external sources (i.e. through lease, subscription, contract, etc.), but use to support their operations. What’s more, by integrating these super intelligent technologies into their asset management solutions, they can remove most of the current constraints caused by human action (whether physical or cognitive) to deliver far greater value.

The result? Innovative systems that not only are incredibly fast and always at work, but also have greatly expanded capacity to almost instantly recognize and respond to patterns, based on past events and observations (the predictive analytics piece).

Of course, this all comes with a big price tag upfront (although you will realize significant returns on the back end) And machines certainly can’t do everything. In fact, you will still need people to ensure that computer-generated, predictive insights are properly executed in the service of improved business performance. Not to mention the need for human interaction in completing such essential responsibilities as exploring new opportunities, promoting company services, and closing productive deals.

But even more important, Stage 4 will demand a far more holistic company culture. One that engages the ecosystem of stakeholders - from employees to customers and everyone in between - in making the big leap into asset management technologies that are disruptive in their own right.

And given that culture change is typically a pretty slow process, that could take awhile. Which is why your best bet is to plan accordingly, with the help of experts who know how to guide you through the process - regardless of where you are in the other three stages of IoT asset management and digital transformation.

That said, please feel free to reach out to us to get the ball rolling.