Trends help companies determine what they should be doing about common challenges and the modern business landscape. Operators across industries are seeking to stay on top of relevant trends to help make the decisions that will shape their company’s operations in the coming year. One type of trend that is applicable across industries but of particular interest to manufacturing operations is trends that have to do with IoT technology solutions. After all, these solutions are designed to help companies meet their goals. By understanding how these technologies are changing, you can better understand the value they can bring to your business operations. Let’s dive into the IoT technology trends of 2024 that manufacturers should know about, breaking down what they mean and how they can inform your company’s transformation.

Increase Your ROI by Investing in AirFinder Everywhere

- Loss Prevention. Reduce the amount of loss that occurs during the supply chain process

- Location Coverage. AirFinder Everywhere uses a combination of GPS, Cellular, and WiFi to determine location everywhere

- Security Alerts. Know when a delay in shipment has occurred so the problem

can be addressed immediately.

1. Enhanced Data Collection for Predictive Analytics and AI

The concept of Artificial Intelligence or AI is in constant discussion in technology trends spaces, but what the existence of and movement toward that technology means for the manufacturing industry is not often clearly discussed. Discussion of AI related trends focuses on the existence and development of AI capabilities, but these capabilities aren’t available to everyone. After all, AI is not self-reliant and cannot exist in a vacuum. This is true for the use of AI in the manufacturing space as well. In order to have access to the benefits provided by AI technology, manufacturing companies must first focus their attention on expanding the data collection capabilities of their key systems across all aspects of their daily operations. For manufacturers, data collection is the true trend behind the current AI craze, and taking increased measures to obtain that critical data is a move that many manufacturing companies are expected to make in the coming year.

Data collection can take a number of different forms and have a number of different focuses depending on what your daily operations look like and what data you want to obtain. Perhaps you want to collect more accurate data on your use of materials. Perhaps you want to have more reliable numbers for daily and weekly production rates. Perhaps you’re more concerned with knowing how tools and equipment are being used or how efficient different segments of your production process are. Investing in automated data collection tools such as an asset tracking solution can help you obtain and store this information with increased accuracy while taking less time from your day. The asset tracking system will collect data in accordance with your programmed specifications, keeping track of where your assets are, how they’re being used, and how long they’re being used. By using these systems across your entire production process, you obtain an accurate representation of your daily operations in data form. This data can then be used to power efforts to implement AI in the future. One of the most fruitful uses of AI within the manufacturing space is within the realm of predictive analytics, which allows you to not only see what’s happening in your daily operations both now and in the past, but to effectively predict the future based on previous data points. This allows you to predict disruptions and address them before they happen, as well as giving you an effective method for shifting focus as demand changes throughout the year or in response to current events.

2. Acceleration of the Discovery and Implementation Process

Some of the trends surrounding IoT technology are less involved with the technology itself and more involved with the process of implementing that technology. Naturally, these trends are of great relevance to not only manufacturing companies, but to any company looking to implement an IoT platform or other solution in the near future. Fortunately, the projected trend surrounding 2024 implementations is that the discovery and implementation process will occur faster, allowing you access to the solutions that you need sooner so that you can start benefiting from them as quickly as possible. IoT providers are more likely to have a streamlined process for sales and implementation in order to help their customers see the results they want to see sooner, backed up by years of experience and accumulated resources, reviews, and knowledge that help customers feel comfortable with their decision with far less back-and-forth.

This process acceleration is a natural result of the maturation of IoT solutions and the maturation of IoT companies. It happens for most new technologies at some point, usually once they’re grown in prevalence and popularity enough that the technology’s continued existence can be said to speak for itself and its own effectiveness and reliability. Once an IoT solution is on the market for long enough, providers are able to better provide reliable references for their solutions when demanded, allowing customers to achieve understanding of a solution’s capabilities and effectiveness sooner and without the need for extended pilots and demonstrations if that’s not what they want. IoT companies have also gained more collective experience in explaining technologies that might not seem intuitive to potential customers, leading to improved understanding in earlier meetings and purchasing discussions. This trend is expected to continue into 2024, with the discovery and implementation process for IoT solutions getting shorter and shorter, allowing manufacturing companies to benefit from their capabilities sooner rather than later and providing a hassle-free experience across the board.

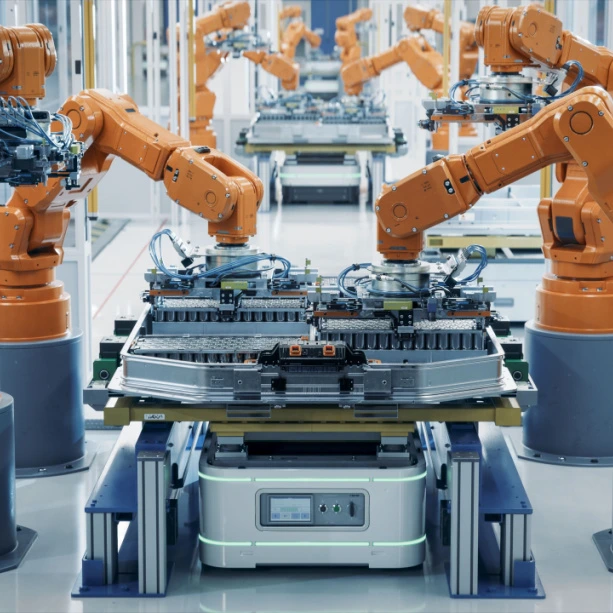

3. Automation as a Supplement to Human Skill

One of the biggest underlying fears concerning automation and other IoT solutions is, for workers especially, that automated systems will replace the human workforce. This fear has stubbornly persisted for years, and while not unfounded, this assumption often inadvertently misunderstands the purpose and capabilities of most automated systems. Very few systems and very few processes can be completely automated by the technology available today; in fact, very few systems and very few processes can be completely automated by the technology that we are currently capable of fathoming for the future. With this in mind, automated systems and the people developing them are largely focused on how automation can be designed and implemented to supplement and support human workers for a more efficient and rewarding work experience. What menial or undesirable tasks can automation take care of so that workers spend more time completing the more skilled and rewarding tasks that they were actually hired to complete? How can automation make daily processes more efficient and less stressful for everyone involved? As we move forward into 2024, more automated systems will be designed and implemented with this focus in mind, as this is where this technology provides the greatest benefit.

Asset tracking systems are one kind of automated system that explicitly exist with the goal of making the lives of both workers and operators easier so that they can spend more time focusing on what’s really important. By utilizing real-time location tracking technology instead of manual spreadsheets or even barcode scanners, no one needs to spend time keeping a manual log of where critical assets such as tools, equipment, materials, and finished products are being used or stored at any given time. Instead, locations are recorded automatically without the need for human input. Not only does this make the process easier, but it also reduces the potential for human error and provides a method for retrieving lost or otherwise misplaced items without needing to initiate a lengthy, time-wasting, stressful search. This is an example of how automated technologies are being used to supplement human skill. The asset tracking technology takes over a menial task and reduces the need for workers to get pulled away from their work. This key focus of automation will continue into 2024 and companies are expected to continue implementing systems with these priorities.

4. Using IoT to Achieve Sustainability Goals

Another current trend about how IoT is expected to be used by manufacturing companies in 2024 is that IoT will be further implemented with the intention of helping manufacturers meet environmental regulations and achieve sustainability goals. There’s an underlying assumption that technology itself is inherently environmentally unsustainable or being used toward environmentally unsustainable ends. While this can certainly be the case, many technology companies are emphasizing more sustainable sourcing and disposal practices for their products, with others going so far as to develop new technologies that actively aid their customers in pursuing and achieving their sustainability goals. This technology can be used to monitor, limit, eliminate, and offset environmental impact, a use that many manufacturers looking to meet environmental regulations and achieve compliance are increasingly taking advantage of.

One technology that can be used to help manufacturing companies achieve their sustainability goals is, once again, asset tracking systems like our AirFinder Onsite solution. Specifically, more and more companies are finding it useful to use our system and other systems like it to better monitor and manage waste collection and disposal. The manufacturing process produces waste; there’s no way around that truth. However, by properly managing and disposing of waste, the negative effect of waste disposal can be minimized and the company can even save themselves some money by keeping a better handle on what materials can still be used. When you track your waste, you’re not going to accidentally dispose of scrap that you intended to keep from later use. It’s also a lot easier to keep recyclables and materials that require special handling and disposal methods apart from everyday waste. By monitoring materials and WIP, you can also reduce the amount of overprocessing that occurs throughout the production process, which further reduces waste by minimizing irreversible production mistakes. These use cases and other use cases with a sustainability focus are expected to be a priority for technology providers and manufacturing companies alike throughout 2024.

5. Expansion and Hybridization of Existing Solutions

To focus more exclusively on the technology and solution development end of technology trends, 2024 is expected to see a trend of expansion and hybridization of existing technology solutions. This means that IoT solution providers will spend more time incorporating new technologies and new capabilities into their current solutions rather than developing wholly new technologies and systems. This is done largely with the intention of attracting and retaining new customers within an increasingly competitive market as more and more technologies and more and more solutions go mainstream. But what does this mean for manufacturing companies looking to invest in technology solutions? Simply put, it means that you can get more out of a single solution, seeing greater benefits at the same affordable price.

Link Labs took strides toward this goal of hybridization in 2023 with our launch of AirFinder Ultra, a specialized version of our existing indoor asset tracking system that combines BLE and UWB technologies to provide greater location accuracy at a reduced cost. This is a notable achievement because UWB, or Ultra Wideband, is a technology that provides the most granular location accuracy, but is incredibly expensive to use and thus not viable for most companies. By combining BLE and UWB for a system that only uses UWB when you need it, we are able to offer the benefits of the technology for considerably less. Efforts like these are what’s making the capabilities of IoT accessible to more people and more companies, allowing you to improve your operations without breaking the bank. IoT providers are expected to continue expanding and combining technologies in new ways to provide more value to their customers throughout 2024, making now the perfect time to invest.

Start Your IoT Journey with Link Labs

Here at Link Labs, we understand the importance of staying up to date with technology trends from both the provider and customer perspective. Knowing what’s important to our customers lets us know what we should be prioritizing in our mission to deliver the most robust, affordable asset tracking solutions for manufacturing and logistics operations. We want to know what’s important to you so that we can ensure that our solutions cover every need that you might have, allowing you to meet your own goals for the new year. To learn more about our asset tracking solutions and how they provide value for manufacturers every day, book a demo with our experts today.