These days, a big focus at Link Labs is our AirFinder product. AirFinder solves the problem of how can an enterprise track, find, and analyze assets and people at a low cost. Cost becomes one of the primary drivers, because given unlimited resources, enterprises would probably track everything, instinctively. Instead, a new tracking project has to be built around a model that seeks to determine the “ROI - return on investment.” So from the get-go, we set out to make a system that could leverage a few drivers that make these types of systems less costly. As I’ve written before, I think of cost in an asset tracking system as breaking down to mostly:

So from the get-go, we set out to make a system that could leverage a few drivers that make these types of systems less costly. As I’ve written before, I think of cost in an asset tracking system as breaking down to mostly:

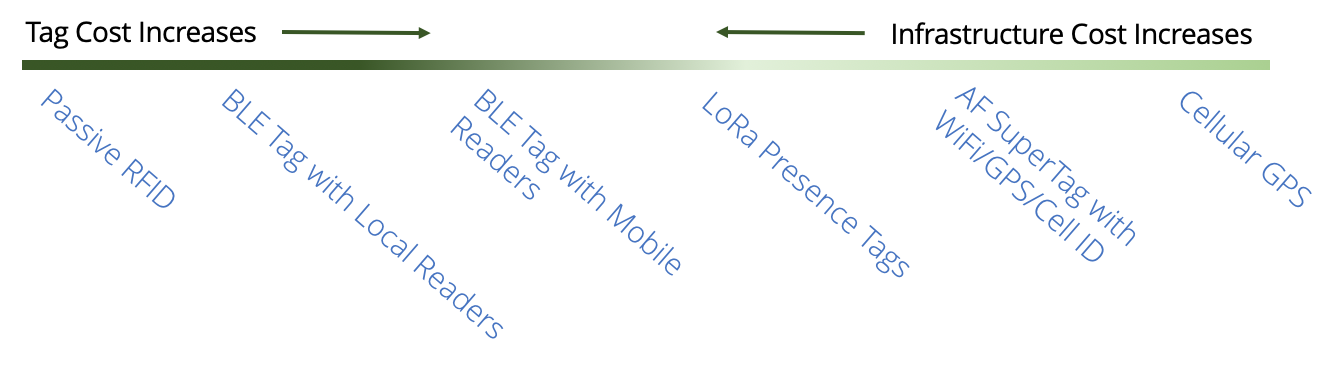

Cost of the tag: This is the most prolific part of any tracking system (hopefully), so it drives the fixed costs the most.

Cost of infrastructure: If the system uses “readers,” how much do they cost? How much do they cost to install, maintain, and connect to the network/internet?

Cost of labor: These systems create a real time burden on those who use them. The hope is that is saves more time than it uses up, but there are costs to managing change, training, and upkeep.

So Why Bluetooth Low Energy (LE)?

Because it makes the tags cost the least.

Of course, passive RFID has even lower tag costs, but those systems make you pay the penalty in terms of infrastructure and lack of location performance. There are still reasons to use passive RFID though.

Bluetooth tags are cheap because:

-

They are mass produced.

-

They use integrated Bluetooth LE SIPs/SOCs that cost $2

-

Can use less complicated batteries because they are more power efficient.

Amazing stuff, but Bluetooth LE has some drawback for Asset Tracking. The Bluetooth LE “link budget” is limited (that’s in exchange for long battery life), so the range isn’t amazing. Therefore, you do need something within 100 ft or so to detect your Bluetooth LE transmission. Luckily, this Bluetooth LE infrastructure is pretty low-cost as well.

The connection point or access point (or reader) that the Bluetooth LE tags are talking to needs to be connected to the network or internet somehow, so that the data can be made useful for asset tracking. This is another key place where cost can creep in.

While AirFinder does have “direct to cellular” access points, we prefer our Symphony Link (LoRa) access points (SLAPs - an acronym I say as much as possible). These allow all those Bluetooth LE message to get back to a central gateway, which can then be backhauled via cellular (or Ethernet). Since the cost-per-SIM is a big driver in cellular IOT costs, this saves a bunch of cellular fees.

Why Cellular?

Because Enterprise networks are under a heavy burden of security management, and just getting permission to connect your Bluetooth LE reader to your customer’s network can take months and reams of paperwork. If you’ve ever had to fill out your customer’s software/hardware security documentation checklist, you know what I’m talking about. A stand-alone IOT network starts to look pretty attractive.

What are the Alternatives to Bluetooth?

Check out this chart.

For most of the enterprise / industrial / manufacturing use cases AirFinder is used for, the alternative is usually Ultra-Wideband. UWB does require an expensive infrastructure, and the tags run about 3-5x more than Bluetooth, but the precision is pretty compelling. We find that many use cases only need high-precision in a few key areas and processes, which is where we can add additional reference point beacons.

Not All Bluetooth Tracking is Created Equal

AirFinder uses Bluetooth in a different way than many systems. Our tags “listen” to “reference point” beacons which allows them to precisely located themselves before reporting this “truth” back to the network. Other Bluetooth LE tag systems just beacon and require the readers to locate them based on raw RSSI data. This creates a few advantages for AirFinder, namely in cost of infrastructure vs. precision and the ability to use low data-rate networks (like LoRa) for backhaul.

Please make a comment below if you have any questions. I will respond!