What is a Returnable Asset?

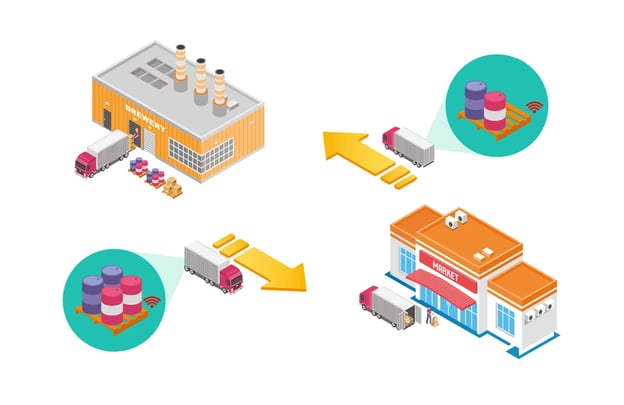

A returnable asset in your facility is returned to its origin after it has been used. They could be used to transport more essential items such as equipment or inventory, but the returnable assets themselves are not generally seen as valuable assets when in reality, returnable assets are actually very expensive if you’re constantly misplacing them. Examples of returnable assets include pallets, bins, and containers.

Why are Returnable Assets Important?

Returnable assets allow you to store and transport your valuable assets much more efficiently. Although returnable assets do not necessarily hold much value, the assets they store and transport are essential to your business. Therefore, if you lose visibility of a returnable asset, you could lose visibility of much more critical assets. Furthermore, if several returnable containers are misplaced or not returned, that could add up to a major profit loss to the company.

The Cost of Not Tracking Returnable Assets

Reusable assets are often not used to their full potential. It is estimated that up to 40% of returnable assets disappear every year for no good reason!

It is easy to not care about the whereabouts of a single $20 pallet compared to the expensive inventory it is carrying. However, when you need to restock those same pallets because of negligence you may have to shell out up to $5000 for a unit of returnable assets.

Oftentimes, companies will purchase more reusable assets than they need to ensure they have enough to meet demand. By employing a real time location system, you will carry the perfect amount of reusable assets you need by knowing where they are, and how they are used at all times. These costs of returnable assets can damage your cash flow which is why you need a better solution to manage your returnable assets.

Increase Your ROI by Investing in AirFinder Everywhere

- Loss Prevention. Reduce the amount of loss that occurs during the supply chain process

- Location Coverage. AirFinder Everywhere uses a combination of GPS, Cellular, and WiFi to determine location everywhere

- Security Alerts. Know when a delay in shipment has occurred so the problem

can be addressed immediately.

Effects of Returnable Assets on Supply Chain

Returnable assets are essential to the supply chain, and one little pallet could be a major bottleneck if used incorrectly. Returnable assets could be bottlenecks because of:

- Misplacement - You cannot improve the use of returnable assets if you do not understand how they are being lost or underused.

- Accountability - It is also important to have accountability with how your returnable assets are used.

- Shipping & Downtimes - Returnable assets play a major role in throughput. By tracking your reusable assets in real time, you will spend less time looking for them in your warehouse which will lead to faster shipping times.

By tracking your returnable assets, you ensure that they are not being underused or misused.

Should You Track Your Returnable Assets?

There is a lot of value in tracking your returnable assets. For starters, instead of placing a tracker on each item on a particular pallet, you could place one tracker on the pallet. This would allow you to monitor these assets more efficiently by tracking the item used to store and transport them.

Many expensive asset tracking solutions do not make sense to put on a returnable asset because the cost outweighs the price of the assets being tracked. Link Labs created AirFinder to solve this problem. AirFinder is an affordable asset tracking solution that gives you real-time visibility of your assets. If you want to learn more about AirFinder, speak with an expert today!